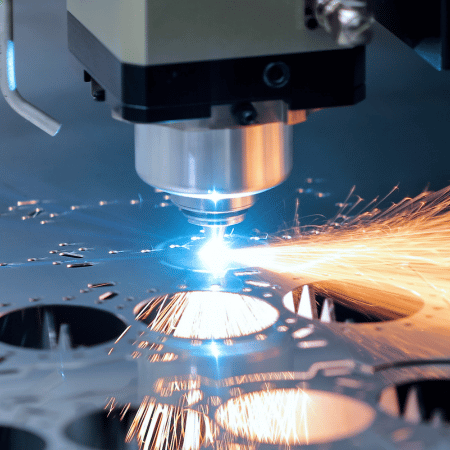

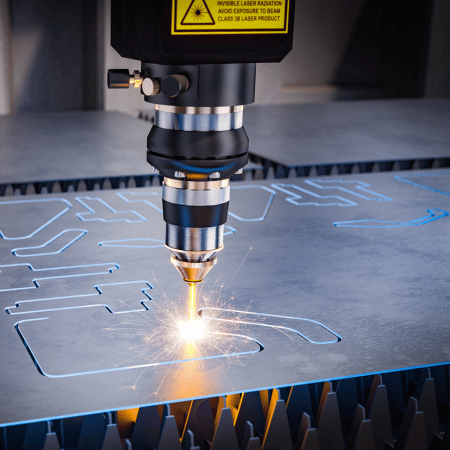

Precision Stainless Steel Laser Cutting

At National Stainless Steel Centre (NSSC), we specialise in providing top-tier stainless steel laser cutting services tailored for a variety of industries and applications. Serving Gauteng, Western Cape, and Sub-Saharan Africa, our cutting-edge technology ensures precision and excellence in every project.

Why Choose NSSC for Stainless Steel Laser Cutting?

Advanced Laser Cutting Technology

Our state-of-the-art laser cutting machines are capable of handling stainless steel thicknesses ranging from 0.5mm to 30mm. These machines provide exceptional accuracy, allowing for intricate designs and precise cuts. Whether your project requires detailed patterns or large-scale production runs, NSSC's equipment and expertise guarantee top-quality results.

High-Volume Capabilities

Efficiency is key in our operations. Our fully automated sheet-loading machines can accommodate plate sizes up to 6m long and 2m wide, making them ideal for high-volume production runs. This capability ensures that we can meet large orders promptly without compromising on quality.

Quality Assurance

At NSSC, quality is our priority. We adhere to ISO standards and procedures, ensuring that every product meets international quality benchmarks. Our experienced staff and advanced processing machinery work together to deliver products that exceed expectations.

Strategic Location

Centrally located in the Aerotropolis mecca of Gauteng, Kempton Park, near OR Tambo International Airport, NSSC is strategically positioned to serve clients across South Africa and internationally. This prime location enables us to provide efficient and timely service, meeting your stainless steel laser cutting needs with ease.

Our Expertise Across Diverse Industries

With over 40 years of combined experience in the stainless steel industry, NSSC has the knowledge and expertise to serve a wide range of sectors, including:

- Agriculture

- Architecture

- Automotive

- Civil and Construction

- Mining

- Petrochemical

- Water and Sanitation

- Private Sector

Our understanding of these industries allows us to cater to their unique requirements with professionalism and precision.

The NSSC Laser Cutting Advantage

Precision and Reliability

Harnessing the power of precision technology, NSSC offers stainless steel laser cutting services that are both reliable and accurate. Our advanced machinery and skilled workforce ensure that each project is completed to the highest standards.

Custom Solutions

Every project is unique, and NSSC is equipped to provide custom solutions to meet specific needs. Our team works closely with clients to understand their requirements and deliver tailored results that align with their vision.

Environmentally Conscious

We are committed to sustainability. NSSC uses energy-efficient processes and recycled materials wherever possible, minimising our environmental footprint while delivering high-quality products.

Contact Us Today

Ready to elevate your project with our stainless steel laser cutting services? Contact NSSC today to learn more about how we can assist you. Whether you need detailed information or have specific inquiries, our knowledgeable team is here to help.

Frequently Asked Questions

-

What are the capabilities of NSSC's laser cutting machines?

- Our machines can handle stainless steel thicknesses from 0.5mm to 30mm and plate sizes up to 6m long and 2m wide, suitable for high-volume production.

-

Why should I choose NSSC for stainless steel laser cutting?

- NSSC combines advanced technology, experienced staff, and a commitment to quality to deliver precise, reliable, and customised stainless steel laser cutting services.

-

What industries does NSSC serve with its laser cutting services?

- We serve various industries, including agriculture, architecture, automotive, construction, mining, petrochemical, water and sanitation, and the private sector.

-

How does NSSC ensure the quality of its laser cutting services?

- We adhere to TUV standards and implement stringent quality control measures to ensure all products meet international quality benchmarks.

-

Does NSSC offer custom laser cutting solutions?

- Yes, NSSC provides tailored solutions to meet the specific needs of each project, working closely with clients to ensure their requirements are met.

-

Where is NSSC located and what areas do you serve?

- NSSC is centrally located in Kempton Park, Gauteng, near OR Tambo International Airport, serving clients across South Africa and internationally.

-

Can NSSC handle large-scale stainless steel laser cutting projects?

- Yes, NSSC is equipped to handle large-scale projects. Our fully automated sheet-loading machines and advanced laser cutting technology allow us to manage high-volume production runs efficiently, ensuring timely delivery and top-quality results.

-

What materials can NSSC's laser cutting machines process?

- NSSC's laser cutting machines are specifically designed to process stainless steel, handling thicknesses from 0.5mm to 30mm. Our equipment is optimised to deliver precise and clean cuts for various applications across multiple industries.

-

How does NSSC ensure quick turnaround times for laser cutting services?

- NSSC ensures quick turnaround times through our strategically located facilities in Gauteng, advanced automated machinery, and efficient workflow processes. Our central location near OR Tambo International Airport also enables us to serve clients across South Africa and internationally promptly.

-

What sets NSSC's stainless steel laser cutting services apart from others?

- NSSC's stainless steel laser cutting services stand out due to our commitment to precision, quality, and customer satisfaction. We use state-of-the-art machinery, adhere to TUV standards, and employ a highly skilled team to deliver customised solutions that meet the unique needs of each client.